(Mobile, AL)

At Challenge Testing, we’ve built a reputation as a leader in engineering testing, with a portfolio of projects and partners that span the globe. From sediment sampling in Taiwan to field testing in Tallahassee, our work takes us to industries and locations as diverse as Guam and Gulfport, Mississippi. One of the key services we offer to industries worldwide is Non-Destructive Testing (NDT)—a game-changing practice that’s essential to ensuring safety, efficiency, and operational excellence.

What is Non-Destructive Testing?

Non-Destructive Testing refers to a suite of techniques used to evaluate the properties, integrity, or performance of materials and equipment without causing any damage. Unlike destructive testing methods that may render components unusable, NDT is non-intrusive and designed to preserve the asset being tested.

NDT is especially critical for industries where downtime is costly, and safety is non-negotiable. It allows us to detect flaws, corrosion, and other vulnerabilities, ensuring the reliability and longevity of crucial infrastructure.

Challenge Testing: Trusted Experts in NDT

Our NDT expertise spans a variety of heavy industries, including:

-

- Energy Generation

- Shipbuilding

- Aerospace

- Marine

- Refining

- Infrastructure Development

Our governmental and private clients have trusted us with projects ranging from Corps of Engineers assignments in Haiti and Puerto Rico to port inspections in Trinidad and the Freeport of Grand Bahama. Whether it’s container crane inspections in Dutch Harbor, Alaska, or hydrographic surveys in Gibraltar, Challenge Testing goes where the work takes us—and delivers results every time.

NDT Techniques We Offer

Here are some of the industry-standard NDT methods we utilize:

- Ultrasonic Testing (UT): Perfect for detecting and sizing flaws or corrosion.

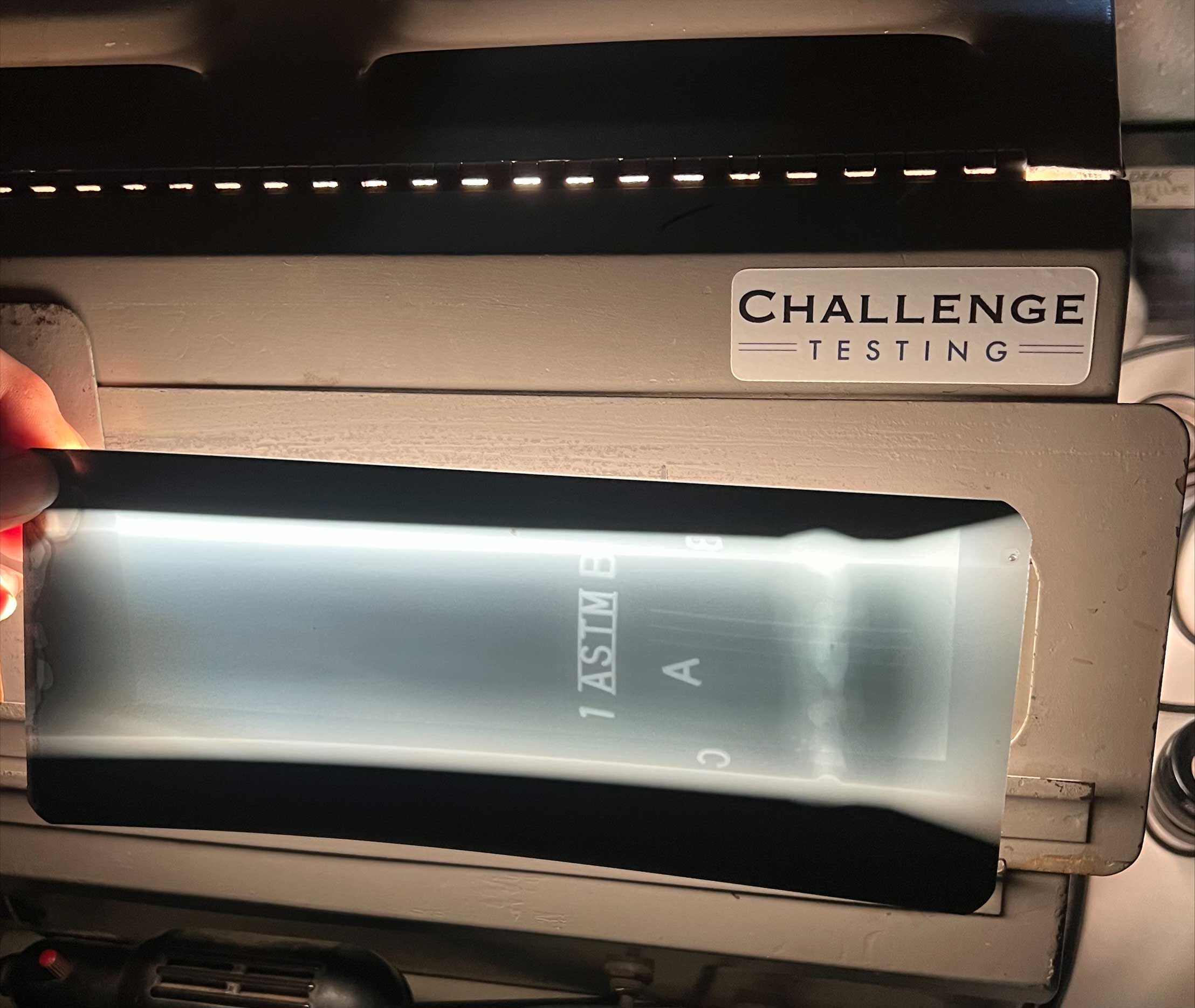

- Radiographic Examination (RT): Uses X-rays or gamma rays for internal inspections.

- Magnetic Particle Testing (MT): Great for identifying surface and near-surface flaws in ferromagnetic materials.

- Eddy Current Testing (ET): Ideal for detecting cracks or material variations.

- Dye Penetrant Testing (PT): A reliable method for spotting surface defects.

Each technique is selected based on the unique needs of the material, environment, and type of flaw being investigated.

Why Does NDT Matter?

Non-Destructive Testing matters because it safeguards lives, protects investments, and enhances operational efficiency. Here’s why it’s indispensable:

- Safety Without Compromise: By identifying issues before they escalate, NDT prevents catastrophic failures in critical systems.

- Maximized Uptime: NDT’s non-intrusive methods allow inspections without shutting down operations, ensuring minimal disruptions.

- Global Compliance: Industries like aerospace, energy, and infrastructure depend on NDT for meeting stringent regulatory requirements.

- Sustainable Operations: NDT extends the life of assets, reducing waste and supporting more sustainable practices.

The Challenge Testing Difference

What sets Challenge Testing apart is our global reach and dedication to quality. Whether it’s confined-space inspections in Miami or marine surveys in Taiwan, our team delivers precise, actionable insights that clients depend on. With decades of experience and a commitment to innovation, Challenge Testing is proud to play a role in maintaining the world’s critical infrastructure.

The Bottom Line

Non-Destructive Testing is more than a technical service—it’s a safeguard for safety, productivity, and trust. At Challenge Testing, we bring decades of experience and a global portfolio to every project, ensuring our clients’ assets stay strong and operational.

Ready to learn more about our work or join our team? Contact us today!

NDT Testing – In the field